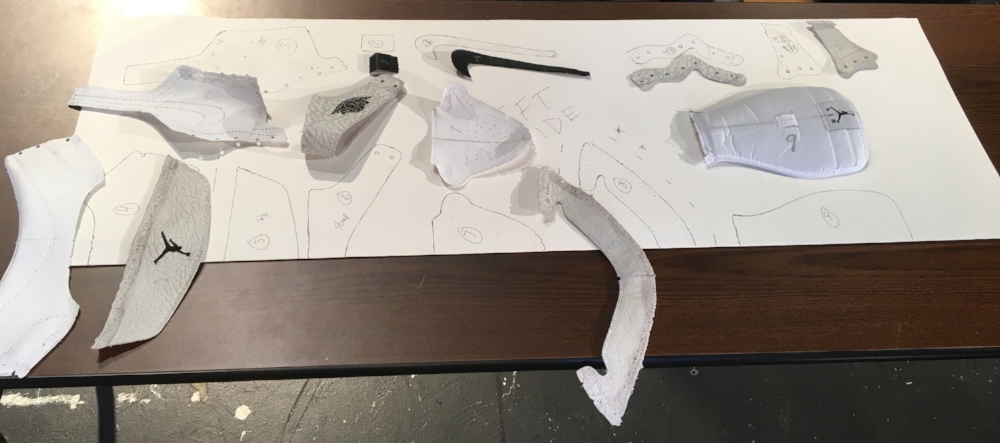

Over 60 hrs of work created a pair of bespoke Air Jordan 1's. The process of making a pair of sneakers is straightforward: cut leather, sew leather, stretch leather, glue on sole.

Even with a straightforward process, the shoe maker has the ability to put creativity and innovation into each pair he creates.

Its All A Process

There were early mornings and late nights, but it was all worth it. Stitching the leather was the toughest part for me. A crooked stitch meant the thread had to be removed and that piece of leather might need to be replaced. There was no room for error.

Dom "The Shoe Surgeon"

The Box

I'm extremely proud of what I created. From the flyknit and leathers down to the lasting and stitching, I made it. I have a Nike sole and a swoosh, but it was made by Aaron.

One of One.

The 11 students came from different backgrounds, but all shared a love for sneakers and making. Throughout the whole class, we learned and worked together. Everyone helped each other realize thier creations. I was grateful and inspired by the way we worked together as a team.

Dinner with the class