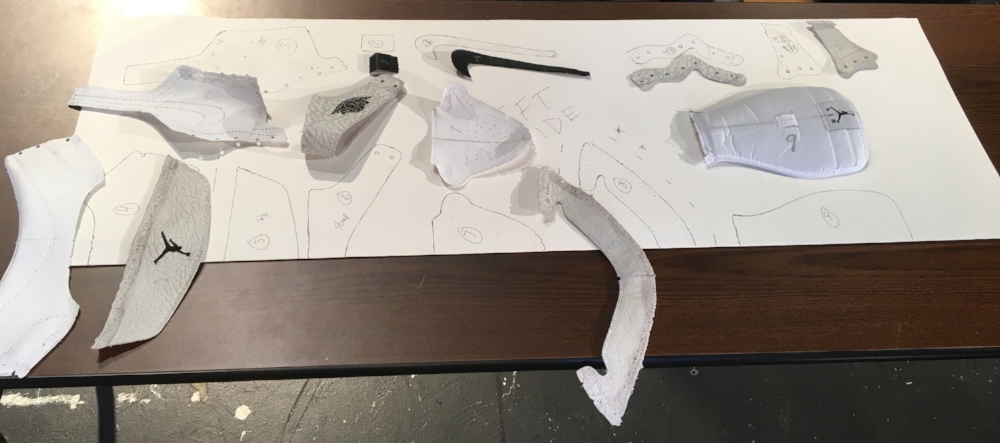

I came in early on Day 2 because I wasn't very confident in the accuracy of my patterns. After removing loose threads and adhesive from the edges and being more deliberate, the re-cut patterns were ready to roll.

Normally, the left and right shoe are made with different patterns. For time and simplicity, we used one pattern to make the left and right shoe. We had to take extra effort to ensure that certain pieces were symmetrical.

Next was material selection. Ecco Leather had so many different colors and textures that it was tough to decide on the 2-3 to work with.

The pair I deconstructed had a white/red outsole, so I knew it was best for the swoosh to match the outsole. 1st color - Red. The design of the AJ 1 incorporates a straight lines throughout (see below), so I wanted to pick a textured natural pattern to offset those lines but also connect with the outsole. 2nd color - black and white textured natural pattern. I went with a natural white leather to balance the pattern. 3rd color - white leather.

Along with the base materials, I choose two accent pieces, a hexagonal stamp pressed leather, along with a swatch of my own deconstructed Airmax 2016 FlyKnit's. The hex and flyknit pieces are my way of infusing technology and personal inspiration into my design.

Here are the four materials I selected for my AJ 1 (brought to you by Ecco Leather.)

Next step was tracing the pattern onto the leather pieces and cutting the material.

The end result from day 2.

UP NEXT - DAY 3 - Skiving and Sewing