Why can't the toe box on my shoes tell me how fast and how long I've been running?

What if you wanted to know the optimal spot on your foot to take a free kick from?

Today, Apple was granted a patent for conductive carbon nanotubes to be used in a fold-able Iphone.

These tubes form flexible strands that hold signals (electricity) and are flexible and resistant to cracking.

Apple has found a way to bend displays and stretch signals over a small folded area.

With the release of the Nike HyperAdapt and Air Mag, there is a push to have shoes be more adaptive and responsive to the athlete.

After the fold-able phone, the smart shoe will be next.

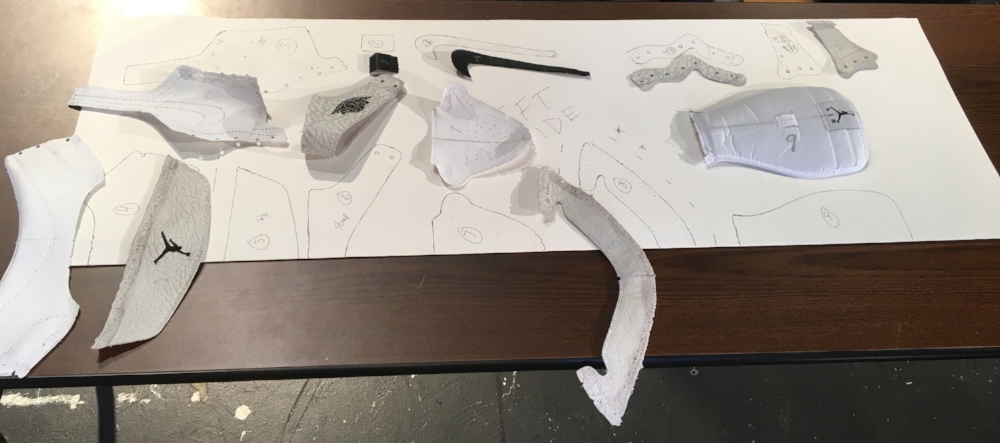

For smart shoes to succeed, the wiring and connections needed to power the shoe have to integrate seamlessly into the shoe.

The guts.

Embedding conductive carbon fibers into a flyknit upper would create a feedback loop for the athlete. Using touch sensors embedded in the sole and upper, an athlete could see stride, speed and impact information displayed on a phone, or directly on the toebox.

A soccer player, who now has a target displayed directly on his boot, to guide him to his strongest spot for a free kick.

The basketball player, who can see how high they jumped for the last rebound.

What if your shoe displayed your running route? The total number of miles ran in the shoes. A text message from home, telling you to buy some milk at the store...

The possibilities are endless.

Sources

http://solecollector.com/news/2015/10/the-hardest-sneaker-to-retro-the-nike-air-mag

http://www.designboom.com/design/interview-with-rob-williams-of-nike-flyknit-lunar-innovations/