The deadline for submission to the Nike Ease Challenge is December 15th, one month away.

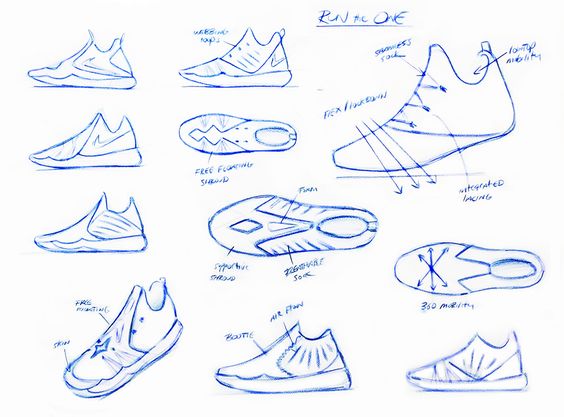

My plan is 2 weeks idea generation, 2 weeks refining ideas, 2 weeks of prototyping.

The challenge for me is to turn off the internal filter during idea generation.

The more ingredients in the idea pot, the better the outcome. Diversity breeds innovation.

When you start wondering ..."if it's already been invented?" the battle for creative freedom has been lost.

There are constraints a shoe designer develops when creating a new design:

- The athlete has full use of both hands for putting the shoe on and off

- The athlete's foot can move during entry and exit of the shoe

- The shoe fit can be adjusted during short breaks in the sports activity

- The athlete can bend over and secure the shoe by tying the laces

The criteria from Nike on the challenge is straightforward:

Successful technologies will be:

Optimized for an easy entry, closure and exit of a shoe

Engineered for high performance and fit

Transferable across a wide range of shoe sizes and styles

Viable solutions ready for prototyping

The traditional footwear assumptions have to be changed for the Ease Challenge:

- The athlete has limited use of one or both hands for putting the shoe on and off

- The athlete's foot cannot arch/move during entry and exit of the shoe

- The shoe fit cannot be adjusted during short breaks in the sports activity

- The athlete cannot bend over and secure the shoe by tying the laces

Nike Hyper Adapt 1.0

I think the winning technology will

- incorporate FlyWire to secure the foot to the sole (high performance)

- Is as easy to put on and off as a loafer or moccasin

- Has an enlarged foot opening for Orthotic braces

- Has a lacing system that can be loosened or tightened with minimal force applied by the wearer

- an flexible dynamic upper for different shapes and sizes of feet

This process has been beneficial for me. Building empathy for the athlete, understanding how difficult it must be to put a pair of shoes with limited mobility. Wanting to be active but not having a shoe that fits your special need in footwear.

For the next 2 weeks, I'll be refining my preliminary concepts:

- Flywire Ratchet Concept

- Flywire Magnet Concept

- Flywire Strain Relief Bend Concept

- Hook and Loop Sock Fastener Concept

- Split Tongue/Magnet Concept

- Modular fit shell Concept

- Woven Hatch Lacing Concept

- Dynamic Buckles Lacing Concept

- Arch Strap Concept

- Clam shell Upper Concept

- Magnetic Flywire Cage Concept

- Foot Latching Lacing Concept

- Hook and Loop Upper Clam shell Concept

Sources