Here are ten books I would recommend you read.

As I grow and evolve as a human, these books have helped me immensely.

I would not be where I am without numerous re-readings of each of these ten books.

There are plenty of reviews on each book, I’ll just give you my quick reason.

The Four Agreements - THE MILLENIAL BUSTER BOOKS

The Alchemist- a story that everyone can relate to, better after the 5th read

Ego is the Enemy- there’s no “I” in team

The Obstacle is the Way- work through your problems, quit avoiding them

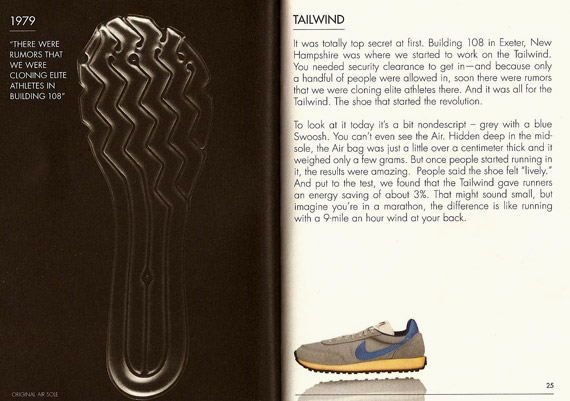

Shoe Dog- how risks and obsessions can create something special

It’s Not How Good You Are…- marketing 101

A Beautiful Constraint- true outside the box stories

How to Win Friends and Influence People- don’t argue, don’t correct, learn people’s names

The War of Art- You are your biggest resistance

Zen Mind Beginner's Mind - Think like a beginner to never stop learning