Hyperbolic geometry is tough to explain, so I dug into youtube to help explain using crocheting as an example.

Traditional flat knitting machines can produce a 1 piece upper, but the end result still requires seam sewing and steam lasting to form to the foot. A hyperbolic knitted/crocheted upper could potentially be made in one complete piece, without the need for lasting. The key is where and how to increase the number of stitches when knitting.

Starting with the strobel as the base standard knit pattern, the hyperbolic knit would sweep outwards around the last spiraling upwards until it met at the top of the shoe. By increasing or decreasing stitches, the upper would loosen or tighten as it wraps around the upper. Creating support zones on the shoe is also an option, The bottom 1/2 could be a stretchy weave to allow for give and the top 1/2 of the upper could be tighter weave to create the support.

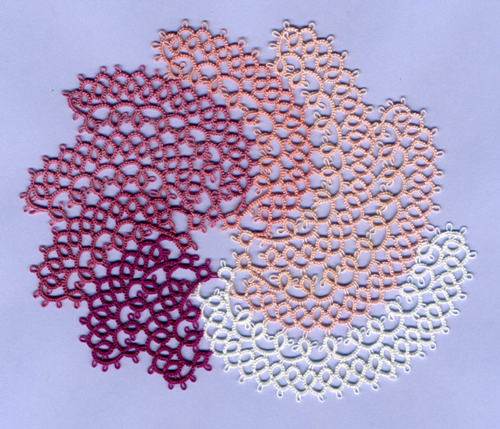

Example

End stitch at the top of the sock.

Hyperbolic geometry is important because it came about back in the 1800's, and wasn't represented in a simple physical model until 1978. Hyperbolic geometry is challenging convention, so it must be important.

“A hundred years ago, the mathematician David Hilbert proved a theorem that it is impossible to represent the hyperbolic plane in three-dimensional space analytically,” he says. “ ‘Analytically’ means ‘with equations.’ Everybody left off the word analytically later on. They were worried that mistakes or errors would creep into mathematics through geometric intuition, and so they discouraged the study of geometry and everything associated with this weird kind of thinking.”